Wire Flexure Rod Assemblies

In an earlier blog, we looked at some ways to connect the Airpot piston to a rod. We looked at a rigid rod connection that is rarely used but good to know about and also briefly touched on our standard ball joint which is the most common connection. Today, we will talk about a very clever rod that is a real problem solver: the wire flexure rod assembly.

A wire flexure is simply a straight wire that is used to connect two objects together. The wire acts to remove one degree of freedom between the objects it connects. The wire should therefore be considered a structural element, not a spring.

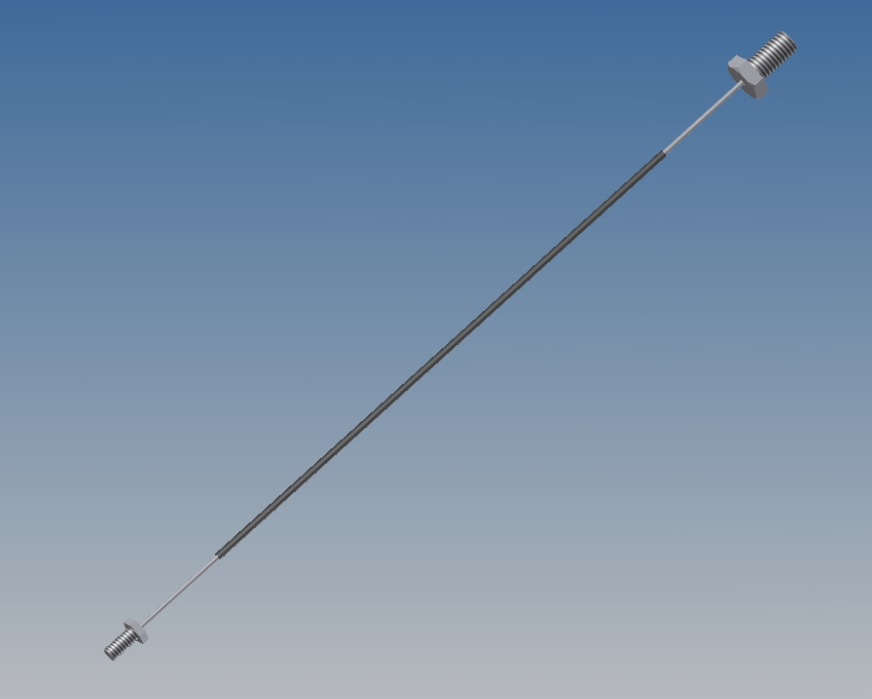

When we design a wire flexure rod, we use a thin (less than 1 mm diameter), straightened spring temper wire that connects to the Airpot graphite piston on one end and the customer’s device on the other end. A wire like this acts like a rod with a ball joint on each end for small motions. However the wire has no joint looseness, no joint friction, and no joint wear like ball joints do. Also, because the wire flexes, it requires no lubrication. Spring tempered stainless steel spring stock is readily available as the wire material. This material has a very high yield strength which is important as we want the thin wire to carry relatively high axial loads.

So we’ve got the 3 parts (Airpot piston, wire, and customer part) but how do we connect them?

- Adhesives like epoxies and industrial anaerobic adhesives are no good because the small surface area of the bond means the bond will be weak and the wire will pull out too easily. The same is true for soldering.

- Press fitting the wire into something involves very tight tolerances and even then will have assembly issues.

- Welding is a problem as the high temperatures involved will cause the wire to anneal, significantly reducing its strength.

- Screw-based clamps can work but must be designed so as not to damage the wire and there is the problem of how to lock the screw.

- Often, the best solution is to braze the stainless steel wire into a larger stainless steel part, like a screw. Brazing gives an amazingly strong connection that can actually be stronger than the wire itself and brazing temperatures are below the annealing temperature of the stainless steel wire.

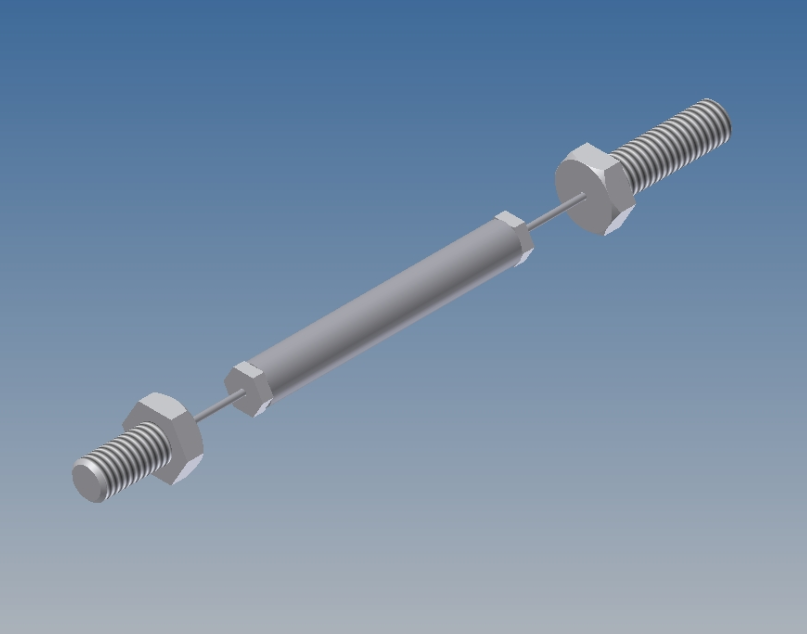

A thicker center section adds some complexity but can give buckling resistance. Below are some examples showing the thicker center section used in wire flexure rod assemblies.